strength + quality = longevity

With an abundance of van builders in the market today, it's easy to feel overwhelmed by the options. When it comes to selecting your van, it's crucial to compare apples to apples. At Alumivan, we pride ourselves on offering unparalleled build quality and utilizing the finest materials, sourced predominantly from the marine industry. Allow us to walk you through the materials we use and why they set our vans apart from the rest.

Structure

At Alumivan, we prioritize strength and longevity from the very start. We begin by building a robust foundation using extruded aluminum, ensuring durability and reliability for years to come. Unlike mass produced vans with stapled together wood builds, our structures are bolted to the van's frame with stainless bolts and factory anodized brackets—no corners cut! Wood construction is still a mainstay in the industry because of it’s low cost and quick assembly times. Here's why we swear by extruded aluminum:

1. Strength and Lightweight: Extruded aluminum offers unparalleled strength while remaining lightweight, making it an ideal material for van conversions. Rest assured, your build will stand firm even during sudden stops or collisions.

2. Dimensional Stability: With perfect dimensional stability, our builds maintain their squareness and strength over time, ensuring a consistently solid structure.

3. Silent Travel: Unlike wood builds prone to squeaks and creaks, our aluminum constructions ensure a quiet ride, free from irritating noises caused by wood rubbing together.

4. Resistance to Moisture: Unlike plywood, which is susceptible to swelling, delamination, warping, and mold growth, aluminum remains impervious to moisture damage. This is crucial given the varying climates a van encounters, as well as the daily exposure to condensation.

5. Versatility: With the inclusion of exposed t-slots, our builds offer endless mounting possibilities. You can easily attach and remove various accessories without leaving permanent holes, thanks to the versatility of aluminum construction. Clients have effortlessly added shelves and other accessories post-conversion, thanks to the simplicity and adaptability of our builds. We believe in providing not just a van, but a customizable and durable platform for your years of adventures.

Panels

We’re committed to providing the highest-quality materials for your van conversion. That’s why we use King Starboard, a premium marine grade material that outperforms traditional plywood in every way.

Unmatched Durability

Engineered to thrive in the harshest marine environments, King Starboard is specifically designed to withstand prolonged exposure to UV rays, moisture, and humidity. Unlike conventional plywood, it won’t swell, delaminate, or rot. These panels last longer and hold up to demanding conditions.

No More Touch-Ups

Painted wood builds quickly show signs of wear and tear, especially in the small, high traffic spaces of a van or RV. King Starboard’s color is consistent throughout the entire board, meaning there’s no need for constant repainting or refinishing. You’ll enjoy a clean, fresh look that stays intact, year after year, with minimal maintenance.

Easy Access & Customization

We understand the importance of convenience in a van build. That’s why our panels are designed to be easily removable with just a few bolts—no need to dismantle your entire setup. This allows you to access components like water pumps and batteries quickly, and makes future upgrades or repairs simple. Plus, if you ever want to switch up your design or replace damaged panels, King Starboard offers flexibility for the long term.

A Worthwhile Investment

While the initial cost of King Starboard is higher than traditional plywood, around $350 per 1/2” sheet compared to plywood’s under $100 per sheet—the long-term benefits far outweigh the difference. Investing in King Starboard means you’re choosing durability, convenience, and peace of mind that will stand the test of time.

We believe in the value of investing in quality materials that offer lasting performance.

Flooring

You’ll quickly notice that we use a wide range of marine grade products rather than typical RV or home materials. The reason is simple: marine products are designed to withstand some of the harshest conditions—constant sun, intense heat, moisture, and saltwater exposure. These tough, high-performance features make them the perfect fit for a van that needs to endure similar challenges.

Our luxury woven vinyl flooring, often found on high-end boats, is a prime example of why marine products excel in a van build. Here’s why it’s the perfect choice:

Tough & Easy to Clean: Engineered to handle the elements, this flooring stands up to wear and tear, making it ideal for everything from everyday use to rugged adventures.

Seamless Design: Unlike vinyl plank flooring, our woven vinyl comes in a one piece design. No seams means no worries about spills seeping through or seams lifting over time.

Comfort Underfoot: Comfy yet durable! The woven texture feels nice on bare feet.

Great Traction for Pets: The texture also ensures your pets can move around with ease, offering great grip and reducing the risk of slips which can scratch plank flooring over time.

Choosing marine grade products means investing in durability, functionality, and long-lasting performance.

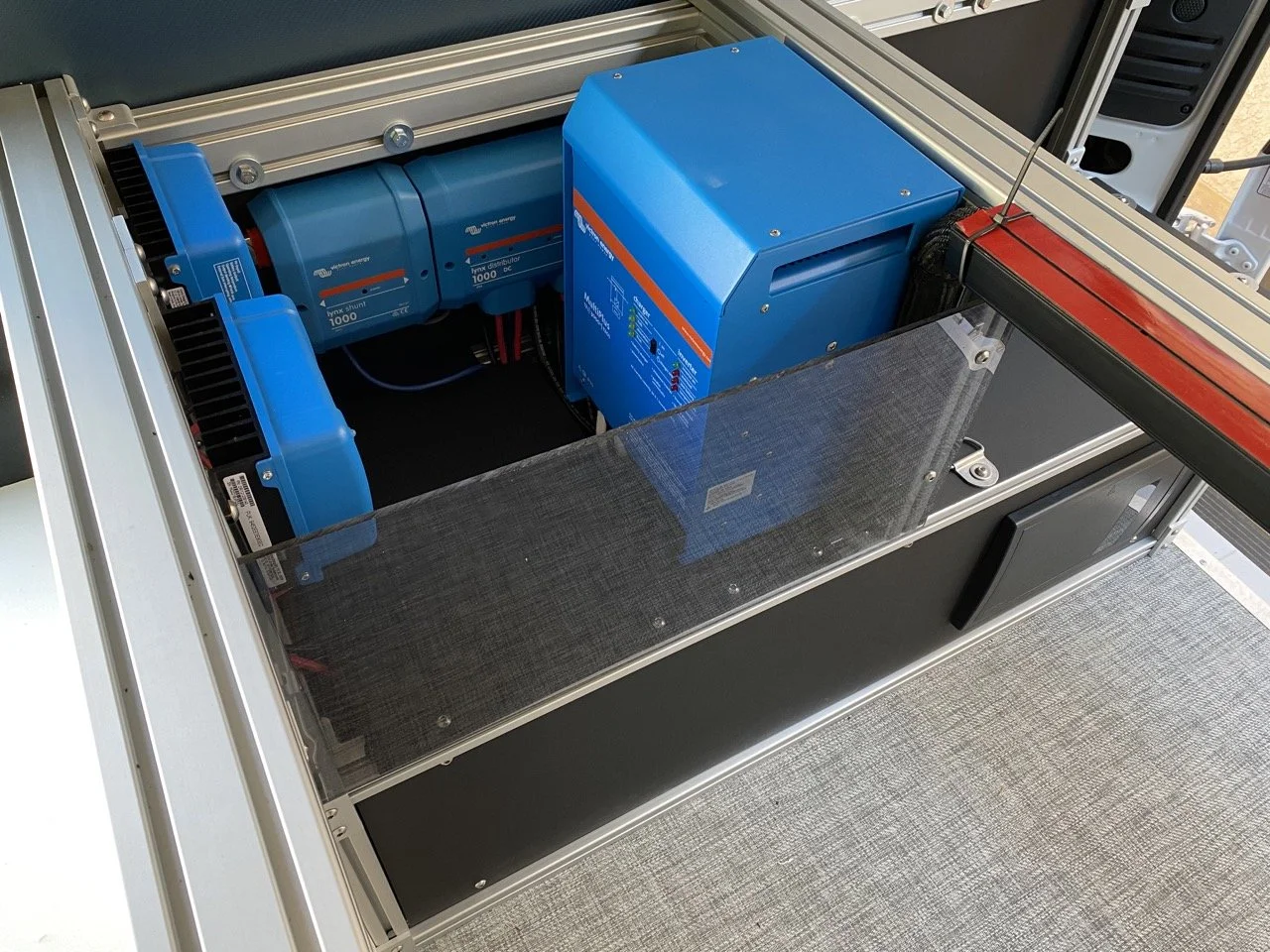

Electrical

We believe in using only the best, which is why we rely on Victron products. These components are trusted worldwide for their durability, performance, and reliability—essential qualities for a van that needs to power your adventures without fail.

Why Victron?

Victron is the leader in marine electrical systems and in recent years it has become the go-to brand for premium van builds. Originally designed for the harsh conditions of the boating world, their products are built to endure extreme temperatures, humidity, and vibration, making them perfectly suited for the changing environments of van life.

Built to Last: Victron products come with a 5-year warranty, offering peace of mind knowing you’re investing in reliable, long lasting components.

Easy Control: Manage your entire system effortlessly via the Victron app and our Cerbo touchscreen monitor, putting full control at your fingertips.

Our standard electrical system includes:

460 amp hours of Epoch lithium batteries

Victron 3000VA Multiplus inverter/charger

Victron 100/50 MPPT Solar Controller

Victron Orion XS 50A DC-to-DC charger

Victron Cerbo GX with touchscreen

Victron Lynx Shunt and Lynx Distributor for system fuses and monitoring

With Victron, you're guaranteed a premium, fully integrated electrical system that provides efficient energy management and long term reliability.

Why Ancor Marine Wire?

For wiring, we use Ancor tinned stranded copper marine wire—the only choice for your van’s electrical system. Here’s why:

Durable and Reliable: Ancor wire features a heavy-duty protective jacket and insulation, designed to withstand the harshest marine conditions without compromising performance.

Vibration Resistance: Stranded wire is specifically engineered to handle the constant vibrations and movement that occur in a van, ensuring that your wiring remains intact and fully functional for many years.

No Household Wiring!: Unlike household Romex wire, which is not designed for automotive or marine environments, Ancor wire is made to stand up to the unique demands of van life.

Quality Matters

The investment in quality matters. You wouldn’t want to entrust your van build to cheap electrical parts that could lead to failures, malfunctions, or safety hazards. The electrical system is the heartbeat of your van.

Choosing quality components ensures you won’t face unnecessary headaches or danger down the road. It’s about long term peace of mind and a system that works seamlessly, trip after trip.

Insulation

We exclusively use 3M Thinsulate SM600L, a premium insulation designed specifically for vehicles. Here’s why it’s the best choice for your van:

Hydrophobic & Water-Resistant: Thinsulate absorbs no water, making it ideal for van life where condensation is inevitable. This prevents mold and mildew growth, ensuring a healthier, safer environment inside your van.

Non-Organic: Unlike natural materials, Thinsulate won’t support mold, bacteria, or other harmful growths, providing long term peace of mind.

Excellent Soundproofing: Thinsulate also acts as a powerful sound deadener, keeping your van quieter and more comfortable, even in noisy environments.

Fire Safety: It passes rigorous flammability tests, offering an extra layer of safety for your build.

Why We Avoid Other Insulation Options

Fiberglass: Commonly used in homes, but not suitable for vans. It absorbs water, and constant vibration could release irritating fiberglass particles into the air in tight spaces—something we definitely want to avoid.

Wool: Popularized by influencers, wool absorbs water in high humidity and can hold it against the van walls, leading to potential moisture issues. Not ideal for van life.

Spray Foam: While it offers good coverage and high R-value, it has two major downsides. First, it can negatively impact air quality. Second, the risk of warping your van’s metal walls is very high, resulting in permanent damage.

With 3M Thinsulate SM600L, you're choosing the best of the best for insulation. Water resistant, mold resistant, soundproof, and safe. It's the ideal solution!

Countertops

We choose Corian and LG Hi-Macs solid surface countertops for their durability and sleek, modern look.

Built to Last: These countertops are designed to withstand the temperature fluctuations and vibrations that come with life on the road. You won’t have to worry about future cracks like with butcher block.

Easy to Maintain: Scratches can be easily repaired, keeping your countertops looking fresh and flawless over time.

Stone-Look, Lightweight: You get the elegance of stone without the heavy weight or the risk of cracking!

With Corian and LG Hi-Macs, you’re choosing a countertop material that offers both style and performance—perfect for the demands of van living.

Drawers & Fronts

When we do use wood, we don’t cut corners. For our drawers and fronts, we use only solid wood to ensure both beauty and strength. Clients can choose from Premium Maple or Walnut for a personalized touch.

Dovetail Drawers: Our drawers are constructed from 1/2” solid maple with precision dovetail joints, mounted on high-quality Blum drawer slides for smooth, reliable operation.

Solid Wood Fronts: We use 3/4” solid wood for the drawer fronts, finished with a high-end spray-on conversion varnish for an ultra-smooth, premium feel and superior protection.

We pride ourselves on craftsmanship—no veneered plywood or laminated MDF here. Only top quality materials made to last and look stunning for years.

Windows

We use only tempered automotive glass in our vans, just like the glass on your car. For secure installation, we use urethane adhesive, the same method used for windshields, ensuring a strong, lasting bond.

Our windows are installed on the sliding door and both rear doors, and all windows slide open with built-in screens for added convenience and ventilation.

Why We Don't Use Trim Ring Windows

Unlike many builders and manufacturers who rely on trim ring windows, which are held in place by tiny screws pinching the window to the van's metal frame, our method provides better durability.

Trim ring windows often lack the build quality necessary for long term use, which can lead to poor performance and issues over time. Our automotive grade glass and urethane bonded installation ensures a reliable, high quality solution that stands the test of time.